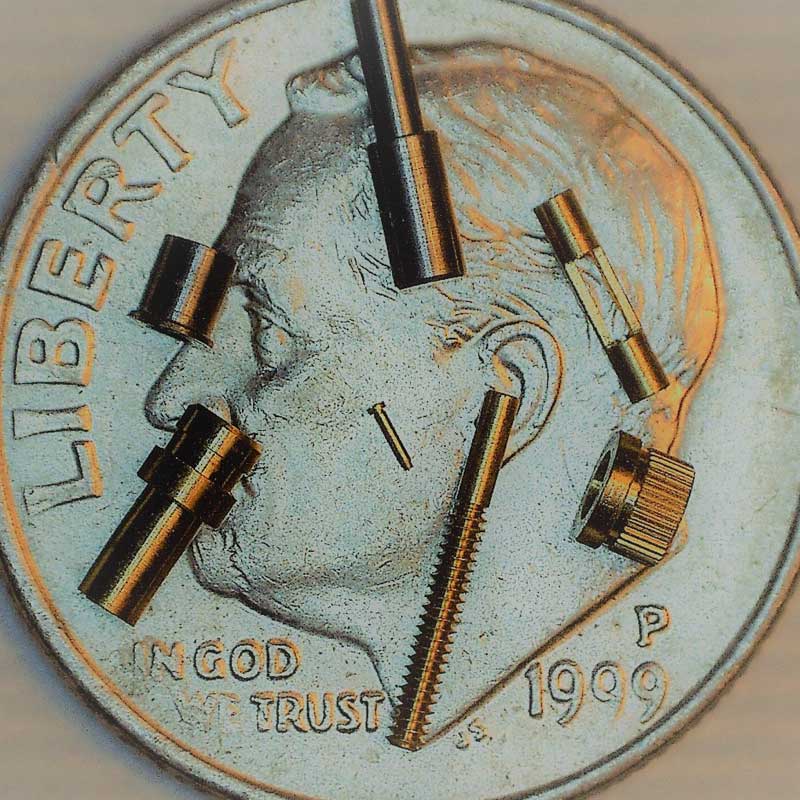

MICRO MACHINING

Lee Machine has done extensive micro machining work for medical devises and micro electronics. With everything getting smaller and smaller we have adapted to current manufacturing demands of machining components as small as .010” and .005” diameters. We have developed expertise at the microscopic level and have equipment to produce an excellent quality part.